Aerosol filling equipment are vital in the creation of many spray-based mostly goods, from deodorants to spray paints. These devices streamline the production system, ensuring precision, consistency, and safety. Important products Within this category consists of the aerosol crimping machine, aerosol gasoline filling equipment, and specialized units such as spray paint can filler and deodorant filling machine. This information explores their capabilities, purposes, and great importance in the economic landscape.

Aerosol Crimping Devices: Making certain a Secure Seal

The aerosol crimping machine plays a vital part in sealing aerosol cans. This machine crimps the valve to the can, developing a protected and airtight seal to forestall leakage and keep merchandise integrity. Correct crimping is vital for making sure the security and operation on the aerosol solution, especially for pressurized contents like sprays and fuel-dependent formulations.

Gas Filling Equipment for Aerosols

The aerosol gasoline filling equipment is built to fill cans with propellants, that happen to be essential for dispensing the product to be a fantastic mist or spray. These machines tackle gases like hydrocarbons, CO2, or nitrogen with precision, guaranteeing the correct strain and quantity for each can. Highly developed gasoline filling equipment boost output efficiency while retaining security standards in dealing with flammable or pressurized gases.

Spray Paint and Deodorant Filling Equipment

Specialized devices such as spray paint can filler and deodorant filling machine cater to specialized niche programs from the aerosol business.

Spray Paint Can Filler: This devices makes sure precise filling of paint items, accounting to the viscosity and needed consistency of spray paint. It makes certain that every can is crammed uniformly to fulfill quality expectations.

Deodorant Filling Device: These equipment are optimized for managing liquid deodorants as well as their involved propellants, guaranteeing exact filling, crimping, and sealing for customer-Prepared solutions.

Aerosol Spray Machines and Liquid Filling Machines

The aerosol spray machine encompasses A variety of functionalities, from filling to crimping and testing, which makes it an all-in-just one Alternative for aerosol production lines. Similarly, the filling machine for liquid is flexible, capable of handling various liquids throughout industries, such as cosmetics, food stuff, and pharmaceuticals.

Benefits of Aerosol Filling Equipment

Precision: These equipment be certain Aerosol Crimping Machine exact filling and sealing, reducing merchandise wastage.

Effectiveness: Automated systems increase production velocity and lower labor expenditures.

Security: Innovative patterns make certain Secure managing of pressurized and flammable products.

Versatility: From paints to deodorants, these machines accommodate a variety of merchandise.

Conclusion

Machines similar to the aerosol crimping Aerosol Spray Machine device, aerosol fuel filling device, and niche methods like the spray paint can filler and deodorant filling equipment are indispensable in nowadays’s manufacturing landscape. They enrich efficiency, retain solution quality, and assure safety in aerosol generation. As industries carry on to innovate, these equipment will stay for the forefront, driving breakthroughs in packaging and products shipping and delivery.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Danielle Fishel Then & Now!

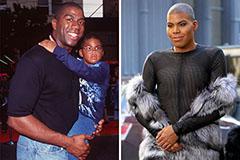

Danielle Fishel Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!